5 Things About ‘The Bear’ That Made Zero Sense and 5 Things About It That Made Perfect Sense

‘The Bear’ blends the intensity of a working kitchen with a grounded portrait of people trying to build something that lasts. It delivers sharp detail on tools, timing, and teamwork while also pushing the limits of what could realistically happen inside a small Chicago restaurant.

This list breaks down where the show stretches plausibility and where it lines up with how kitchens actually run. Each point focuses on practical details anyone who has worked in restaurants will recognize, from permits and payroll to mise en place and vendor calls.

Zero Sense: Overnight remodel and permits

Turning a neighborhood sandwich shop into a fine dining space usually requires architectural drawings, health plan review, building permits, fire suppression approvals, grease interceptor specs, and multiple inspections before a certificate of occupancy is issued. Even a light remodel that touches plumbing, electric, ventilation, or hood systems can trigger plan submissions and rechecks, which often take weeks between each stage.

Lead times add up fast once equipment and finishes are involved. Custom stainless tables, a new hood, walk-in components, millwork, flooring, and banquette upholstery typically ship on schedules measured in weeks, and delivery must line up with trades like electricians and plumbers. Keeping any part of the space operational during heavy construction is possible but requires phasing, dust control, and separate inspections that slow everything down rather than speed it up.

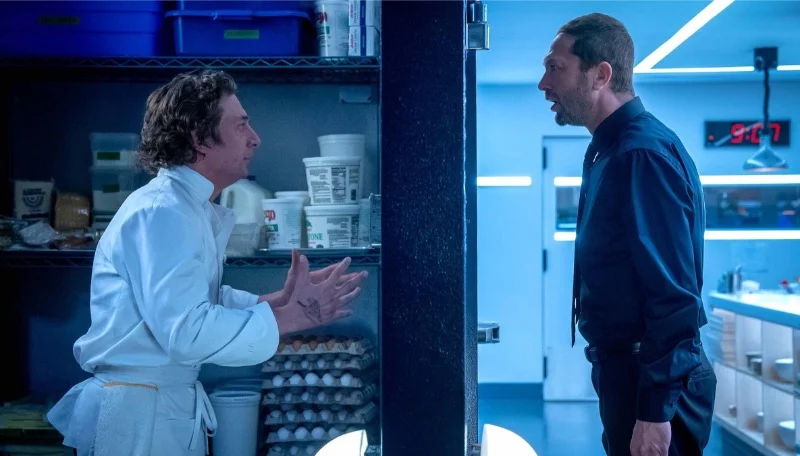

Perfect Sense: Real brigade flow on the line

The show uses clear call-and-response and an expo who controls pacing, which is how a well run line moves food without clogging the pass. Tickets are split into fires and finishes, pans are staged, and stations communicate changes on the fly so courses land together.

Small habits are shown with useful precision. Cooks label and date containers, stack hotel pans to match the board, and keep backups of key components within reach so nobody abandons a station mid-service. These are the little systems that actually protect ticket times and food quality in a tight kitchen.

Zero Sense: Star recognition moving too fast

Recognition from the famous red guide is based on repeat anonymous visits, consistency over time, and a formal annual list. Inspectors do not announce themselves and normally return across seasons before a decision is made. That timeline makes quick leaps from new menu to major accolade unlikely for a brand new room still learning its service rhythm.

Even when a restaurant is on a watch list, the path involves months of steady output under pressure. Teams typically refine menu pricing, sourcing, portion sizes, and coursing while tracking feedback patterns and maintaining stability across days and shifts. A few impressive services do not create the documented consistency those awards require.

Perfect Sense: Service feels like controlled chaos

The sound of printers, the tempo of short confirmations, and the clipped phrasing at the pass mirror how busy services actually feel. Cooks use shared shorthand so a six-top with staggered fire times does not confuse the board, and expo repeats modifiers to prevent wrong plates from leaving the window.

The show also gets recovery mechanics right. When a station falls behind, others quietly reassign tasks like firing garnishes or finishing proteins while expo stretches pacing by sending a course early or holding one item to land the rest. That kind of minute-to-minute triage is how real teams keep a dining room calm while the kitchen runs hot.

Zero Sense: Instant front-of-house mastery

High-end service training usually covers steps of service, seating charts, point-of-sale logic, table maintenance, tray handling, and menu and beverage knowledge deep enough to discuss pairings and answer sourcing questions. Building that range takes repetitive practice and table time, not a single short stage.

Polish shows up in dozens of tiny, learned moves. Staff learn to read pacing by glass levels and body language, clear silently in a pattern so nothing is missed, and sync with the pass to avoid dead time between courses. Becoming fluent at that choreography with confidence in a new room is a gradual process that normally spans weeks.

Perfect Sense: Thin margins and vendor realities

The constant worry about invoices, credits for short shipments, and price jumps on staples reflects daily restaurant math. Operators track food cost and labor against sales while watching prep yields on costly items, because a few off cuts or a bad trim day can erase a service’s profit.

Vendor relationships are shown as essential rather than optional. Reliable purveyors can offer split cases, hold a favorite lot, or run a rush delivery before service, and those favors are built on steady orders and quick payment. That is how small teams keep menus stable when supply swings.

Zero Sense: Training pace for a new menu

Rolling out a tasting menu or complex à la carte set typically involves standardizing recipes, scaling batch prep, writing station guides, and running timed mock services to find bottlenecks. That process reveals which components fail under heat, which garnishes die on the pass, and where plating needs to simplify for consistency. Doing all of that in a handful of days while also opening to guests is an avoidable risk.

Staff scheduling and legal requirements add friction that cannot be ignored. New hires need food safety onboarding, tip reporting setup, and time to pass basic tastings so they can describe dishes accurately at the table. Compressing those steps invites mistakes that real teams normally work out in controlled tests before inviting critics and regulars.

Perfect Sense: Chicago roots and the beef DNA

The show treats Italian beef as a craft with clear steps that locals will recognize. Bread choice, how long rolls kiss the jus, how thinly beef is sliced, and the cut of giardiniera all affect texture and drip, and those decisions are shown as deliberate rather than improvised.

Neighborhood details add texture that reads true. Suppliers, family spots, and back-of-the-house slang link the characters to a specific city food culture where sandwiches, dogs, and steaks carry strong loyalties. That grounding explains why changing a beloved shop requires care with regulars as much as skill in the kitchen.

Zero Sense: Build-out costs vs available cash

A full conversion needs more than new paint and a logo. Hood systems, make-up air, fire suppression, upgraded electrical panels, a compliant dish area, ADA considerations, and code-approved restroom changes can consume a large share of a budget before a single chair is purchased. Leasing terms and security deposits also tie up cash that cannot be spent on the line.

Carrying costs continue while revenue is limited. Interest on loans, insurance, utilities, and payroll for managers who are training before opening all hit the books. Without a realistic contingency for overruns, even small surprises like slab cuts for drains or asbestos abatement can stall a project that looks smooth on paper.

Perfect Sense: Grief, family ties, and kitchen coping

The kitchen is shown as a place where people channel grief into repetition and precision, which matches how many cooks manage stress. Prep lists, sharp knives, and clean stations give structure when life outside the walk-in is messy, and the show makes that structure part of the characters’ survival rather than just their job.

Family dynamics are treated as something that follows people into service. Old conflicts surface during rushes, and breakthroughs happen during late prep or staff meal when guards are down. Restaurants often become chosen families that hold people up during hard stretches, and that reality supports the story’s core relationships.

Share your own sense and nonsense picks from ‘The Bear’ in the comments.