Top 10 Coolest Things About Iron Man

Iron Man stands out because his story is driven by engineering, iteration, and practical problem-solving. Tony Stark doesn’t just wear a suit—he prototypes, tests, and refines systems that integrate power generation, propulsion, control surfaces, targeting, and life-support into a single platform. Each upgrade addresses a specific constraint: survivability, endurance, maneuverability, or mission profile.

Across comics, animation, and films like ‘Iron Man’, ‘Iron Man 3’, and ‘Avengers: Endgame’, the armor evolves from bulky mechanical assemblies to compact, on-demand nanotechnology. Along the way you see modular weapon bays, redundant power routes, adaptive materials, and AI-assisted operations—all designed to reduce latency between intention and action while keeping the pilot alive in hostile environments.

The Arc Reactor Power Core

The arc reactor is a compact, clean energy source that converts palladium—or later, a synthetic element—into high-density electrical output via a miniature fusion-like process. In the suit, that output is routed through bus lines to power servos, flight systems, repulsors, and the life-support stack. The chest-mounted unit also serves as an electromagnetic shield for shrapnel containment in early iterations.

At scale, Stark builds larger arc reactors to power facilities, demonstrating load balancing, failover capacity, and grid integration. The portable versions show hot-swappable cores, thermal management through heat sinks in the breastplate, and current regulation that prevents brownouts when multiple subsystems spike simultaneously during combat maneuvers.

Powered Armor Exoskeleton & Servos

The armor uses a hybrid exoskeleton combining rigid plates with articulated joints, distributing force through a frame that amplifies the wearer’s strength. High-torque micro-servos and rotary actuators at the shoulders, hips, knees, and ankles provide lift and leverage, while shock-absorbing materials protect against kinetic impacts.

Sensor-driven motor control monitors joint angles and load in real time, preventing over-rotation and servo stall. Power assistance scales with intent, translating subtle movements into amplified output so the pilot doesn’t fight the suit. Redundancy in actuator clusters allows partial functionality even after localized damage.

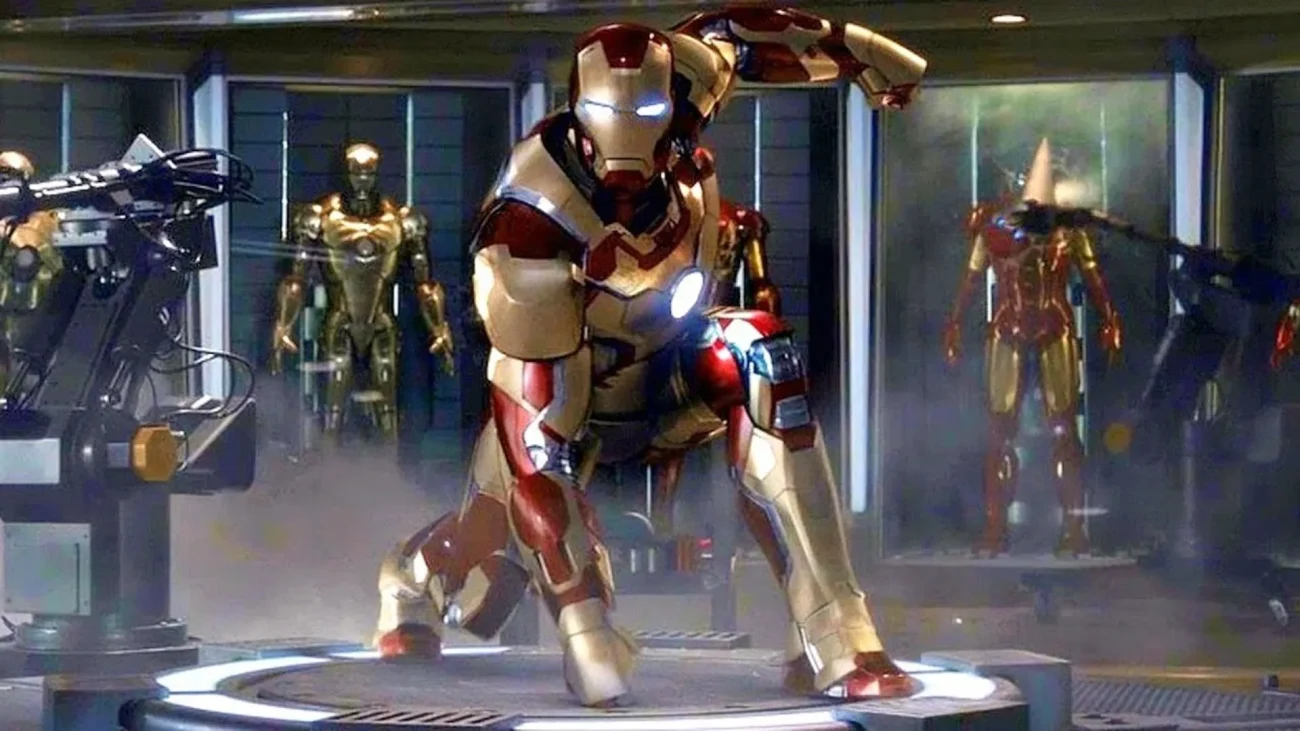

Repulsor Gauntlets and the Unibeam

Repulsors in the palms emit focused energy pulses for both propulsion trimming and offensive output. Their firing solutions consider stance, center of mass, and recoil management to avoid destabilizing the pilot. Energy modulation shifts between wide-angle blasts for area denial and concentrated beams for armor penetration.

The unibeam in the chest is a higher-throughput emitter tied more directly to the main power bus. It’s typically reserved for short, high-intensity discharges due to thermal load, with heat spreaders and timed firing windows to prevent component failure. Targeting integrates with the helmet HUD for rangefinding and threat prioritization.

Flight System, Stabilizers, and Maneuvering

Primary lift comes from boot thrusters, with palm repulsors acting as vectoring jets to manage pitch, roll, and yaw. Flight control software fuses inertial measurement data with gyroscopic feedback to maintain stability at varying speeds and altitudes. Micro-gimbals in the thrusters enable fine-grained attitude control during hover and rapid course corrections.

Aerodynamic design reduces drag and buffeting, while distributed control loops compensate for crosswinds and wake turbulence. Emergency routines handle engine flameout scenarios, triggering autorotation-like descent profiles or deploying retro-thrusters to bleed speed before impact.

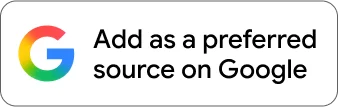

Nanotech “Bleeding Edge” Armor

Later-generation suits use programmable nanomaterials stored in compact housings that deploy across the body on command. The nanites form structural plates, internal supports, and even specialized tools or weapons, reconfiguring in response to damage or mission needs. This allows rapid repair of compromised sections without returning to a workshop.

Resource allocation becomes a tactical choice: forming a large cannon or shield consumes nanite mass that can’t simultaneously reinforce other areas. Thermal limits and power draw are monitored continuously, recalling or redistributing nanites when hotspots exceed safe thresholds to avoid cascade failures.

AI Co-Pilots: J.A.R.V.I.S. and F.R.I.D.A.Y.

J.A.R.V.I.S. and later F.R.I.D.A.Y. function as real-time operating systems, mission planners, and threat-analysis engines. They process sensor feeds, maintain situational awareness, and adjust suit parameters faster than a human can react. Voice and HUD interfaces minimize pilot workload, surfacing the most relevant alerts and options.

These AIs manage communications, encryption, and data fusion from external networks, drones, and satellites. They can sandbox hostile code, run predictive models on opponent behavior, and coordinate multi-suit operations, all while maintaining health checks on power, hydraulics, and environmental seals.

Helmet HUD, Sensors, and Targeting

The helmet integrates a heads-up display with augmented-reality overlays, combining LIDAR-like mapping, radar, thermal, and optical feeds. The system renders trajectory predictions, friend-or-foe markers, and structural weak points based on materials analysis and prior encounter data.

Eye-tracking and gesture inputs let the pilot select targets and tools without removing hands from flight or combat postures. Adaptive brightness, anti-glare coatings, and redundancy in imaging sensors preserve visibility in smoke, darkness, or blinding light conditions, while onboard storage caches maps for GPS-denied environments.

Life-Support, Environmental Seals, and MedTech

The suit features a closed-loop rebreather, temperature regulation, and pressure control for high-altitude or underwater operations. Filters handle particulates and chemical agents, and the inner lining includes fire-resistant and impact-dissipating materials to mitigate blast and heat exposure.

Medical subsystems monitor vitals—heart rate, oxygen saturation, and intracranial pressure—triggering alerts or auto-injectors when thresholds are crossed. The armor can constrict to stabilize fractures, deploy hemostatic agents for bleeding control, and maintain a breathable atmosphere if external air becomes compromised.

Modular Weapons and Mission Loadouts

Iron Man’s loadouts are modular, with hardpoints and internal bays that can host micro-missiles, sonic devices, EMP emitters, or cutting tools. The configuration is selected per mission profile, balancing weight, power consumption, and engagement range.

Targeting software links each module to the HUD, enabling lock-on sequences, salvo timing, and countermeasure deployment. Ammunition tracking and heat budgets ensure weapons don’t exceed safe operating envelopes, and quick-detach mounts allow jettisoning damaged or expended units to regain maneuverability.

Remote Operation and Multi-Suit Protocols

Stark can pilot suits remotely, leveraging secure links, signal hopping, and anti-jam protocols. Telemetry streams allow the operator to issue commands while the suit executes low-latency stabilization locally. In swarm scenarios, suits share sensor data to create a composite picture with improved threat detection.

The “House Party Protocol” showcases distributed tasking where each unit takes a role—breach, shield, evac—based on capabilities and current status. Collision avoidance, deconfliction of fire arcs, and shared power-state updates prevent friendly interference during complex operations.

Enjoyed the breakdown? Share your favorite Iron Man tech detail in the comments!